We are tireless in our mission to minimize oil consumption, decrease fuel consumption, reduce waste oil, increase efficiencies and conserve resources for our customers.

The ONBOARD® Assembly Line, Mesa AZ.

ONBOARD® is a disruptive technology that is committed to providing a cost-effective alternative to traditional oil changes. We are tireless in our mission to minimize oil consumption, decrease fuel consumption, reduce waste oil, increase efficiencies and conserve resources for our customers.

The ONBOARD® Filter Element.

Whether you are an independent or are operating a diesel fleet, heavy-duty equipment, marine vessels, or hydraulic systems, the ONBOARD® ECVD System will dramatically improve your bottom line by extending the life of your diesel engine and increasing the time between engine overhauls due to running on continuously clean oil.

Oil never loses its lubricity—its lubricating capacity. It becomes contaminated with particles and liquids like water, fuel and chemicals.

What is Oil Filtration?

Oil filtration technology has been around for over 80 years. All have had challenges staying on track with OEM changes and technology advancements for each new formulation of lube oil. Bypass oil filters have been proven to extend useable engine life by up to 63% and there have been no documented cases of catastrophic engine failure due to the use of bypass oil filtration. There are several other bypass oil filtration products on the market with a range of effectiveness.

The ONBOARD® Advantage

ONBOARD®’s patented Vacuum Dehydration process removes contaminated gaseous vapors from the crankcase and collectively returns them to the combustion chamber for re-burn.

We have created a product that refines oil while the engine is running, decreases fuel consumption by decreasing friction, and avoids polluting soil and water and, if possible, preserves air quality. In addition we wanted to cut operators’ costs. Our product presents a cheaper, simpler, smaller and more convenient way to maintain an engine.

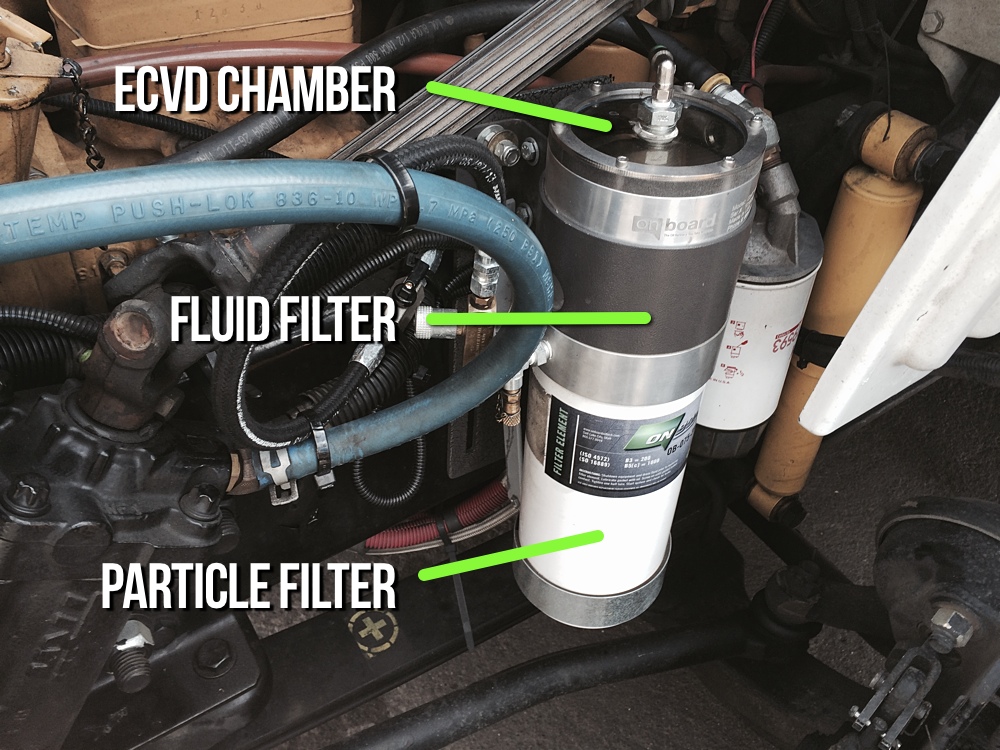

A typical ONBOARD Installation takes very little time

ONBOARD® utilizes a two-stage system:

Stage I – The Particle Filter

The Original Equipment Manufacturer’s (OEM’s) filter system blocks particles down to 20 microns; if they filtered smaller particles, OEM filters would quickly clog up. The ONBOARD® ECVD Particle Filter removes particles to 3 microns. This glass element filter is an integral part of the ONBOARD® ECVD System, and can extend engine life up to 63%.

Stage II – The Fluid Filter

But the ONBOARD® ECVD System has much more to contribute than that. After oil goes through the Particle Filter, it moves to the Evaporation Convection Vacuum Dehydration (ECVD) chamber where water, fuel and other undesirable liquids evaporate and cycle back for re-burn in the combustion chamber. Thus, the engine itself is actually part of the oil refining process! This results in a free-fuel scenario that would have otherwise been lost.

Component Specifications

Patented Evaporation Convection Vacuum Dehydration Chamber

The evaporation and convection processes that extract water, fuel and other liquids from motor oil occur in the ECVD Chamber of the ONBOARD® ECVD System.

The ONBOARD® ECVD Chamber

ECVD: Hard at Work for your Engine

The evaporation rate of contaminating fluids in oil will increase in proportion to the head unit’s surface area. The greater the exposed surface, the faster the evaporation, because water molecules need to be on the oil’s surface to evaporate. With a bigger area, more water molecules are on the surface of the oil, thus more water can evaporate. The evaporation rate depends on the environment of the liquids, temperature, humidity, amount of adjacent air and air movement. Also convection, the heat transfer of a gas or liquid by air current circulation (the phenomenon that makes water and fuel vapors rise and escape the oil), depends on the surface area of the exposed liquid.

To enhance the Evaporation Convection processes, oil emerges at the top of a heated ramp and slides down to the bottom. The ramp is heated by a 12 or 24V heating unit located strategically outside the chamber.

Air comes into the chamber and blows over the convection ramp. Fuel and water vapor rise, and the incoming air circulates out, taking the vapor with it. Water vapor and unburned fuel return to the air intake of the engine for re-burn, adding to engine combustion rather than polluting the environment. Thus the engine itself, with the unique ONBOARD® ECVD System, contributes to the oil-refining process.

Figure 1: Illustrating the difference between absolute and nominal filter efficiency.

The flow rate of oil in the ONBOARD® ECVD System will depend on 1) the oil pressure, which varies both in engine models and in their applications, and 2) the temperature and viscosity of the oil. In general, oil flow is estimated at 3 to 4 gallons per hour.

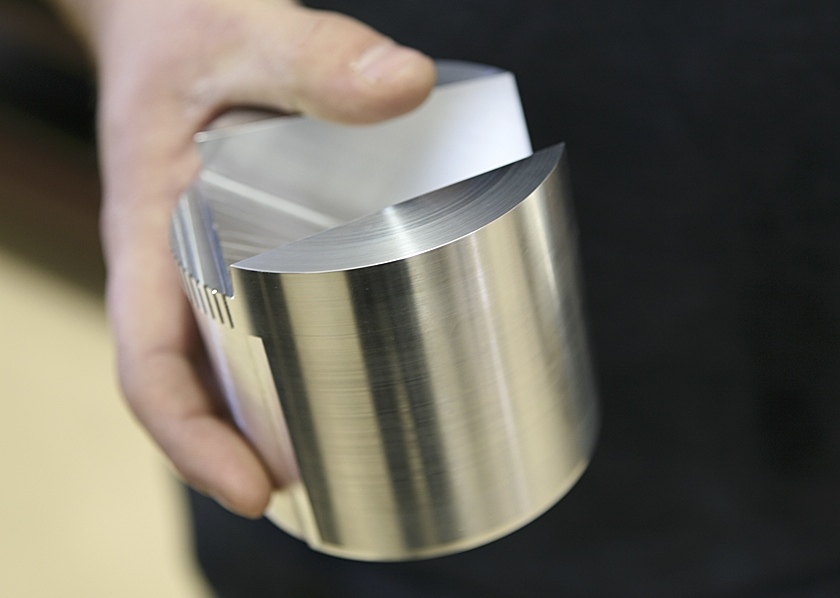

The ECVD Chamber is fabricated in the USA from 6061 aircraft grade aluminum for maximum durability and strength, while keeping weight to a minimum.

Inside The ONBOARD® Particle Filter

The filter element of the ONBOARD® ECVD System uses the latest generation of G8 glass elements. Today’s industrial and mobile hydraulic circuits require elements that deliver specified particle filtration under all circumstances. Wire mesh supports the media to ensure against cyclical flow fatigue, temperature, and chemical resistance failures that occur in filters with synthetic support mesh.

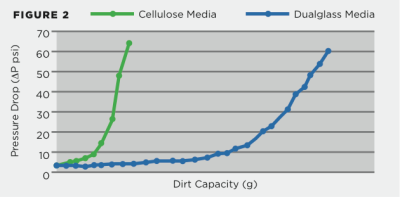

Glass media, compared with cellulose, is more compatible with hydraulic fluids, synthetics, solvents, and high-water-based fluids. Glass also has a significant filtration efficiency advantage over cellulose and is classified as absolute, whereas cellulose efficiency is classified as nominal.

ONBOARD® ECVD System uses an absolute 3 micron, Beta 1000 element. Elements of different media with the same micron rating can have substantially different filtration efficiencies. Figure 1 illustrates the difference between absolute and nominal filter efficiency.

Glass also has much better dirt holding capacity than cellulose. Figure 2 illustrates that a glass element can last 4-5 times longer than a cellulose alternative.

Figure 2: A glass element can last 4-5 times longer than a cellulose alternative.

ONBOARD® Heating Element

The ONBOARD® ECVD System uses a precision cartridge heater that provides localized heat to restricted work areas requiring close thermal control. The US-made heating element is below the outside surface for maximum heat transfer, minimum core temperatures, and faster heating. It is packed in magnesium oxide, rests on a ceramic element support and is covered by a Series 300 stainless steel sheath.