We are on board for the kids and the environment. And we are not just talking about it.

A large step to reduce the oil consumption and its impact on the environment can begin today if everyone becomes aware of their ability to contribute by adopting supplementary oil filtration such as the ONBOARD® System. As ONBOARD® expands its reach, the reduced carbon chain is compounded significantly.

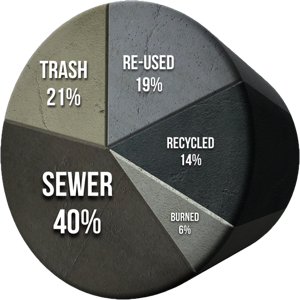

Did you know that one gallon of improperly disposed of oil can render a million gallons of water undrinkable? That’s a high price to pay. This graph shows where the waste oil goes now.

Implementing ONBOARD® Performance Products will dramatically advance your company’s quest to attain maximum sustainability while at the same time, bring an astounding increase to your bottom line. There is far too much at stake to ignore the real opportunity of ending your production of waste oil while improving the lifespan and operations of your fleet.

It Takes a New Perspective

Many consider environmental initiatives in terms of fuel mileage, but the elite knows there is much more they can be doing to protect the environment and earn credibility. Astute organizations are aggressively seeking out additional technologies that can affordably help them minimize negative effects on the environment, and if improving their bottom line comes with it, AMAZING! The ONBOARD® System drastically reduces oil consumption and the environmental risks associated with the dangerous responsibility of handling waste oil. As ONBOARD® expands its reach, the reduced carbon chain is compounded significantly.

ONBOARD® Environmental Benefits

- Increased sustainability

- Reduced hydro-carbons

- Reduced oil consumption

- Reduced waste oil production

- Reduced exhaust vapors

- Reduced filters in the landfills

ONBOARD®’s Technology Dramatically Increases Efficiencies

The ONBOARD® System uses crankcase gases to complete the evaporation and convection process. The vapors are not released to the atmosphere, but instead are re-burned in the combustion chamber. This process reduces the carbon build up in the combustion chamber and soot and fuel dilution are virtually eliminated.

Increased Fuel Efficiency

Clean oil is crucial to the proper operation of large diesel and CNG engines. Dirty oil causes additional friction requiring extra fuel to compensate. ONBOARD® customers have been reporting fuel savings ranging from 8-13%.

It’s a fact. The ONBOARD® Performance Products Help Preserve The Environment

Let’s consider how the ONBOARD® System works.

ONBOARD® Particle Filters utilize the latest generation of G8 dual-glass filter elements capable of eliminating particles from your engine’s oil down to 3µ in diameter. Standard full-flow oil filters only remove particles down to 20µ in size, but studies have shown that over 60% of all engine wear is caused by particles in the 5µ to 20µ range. The dirt-free oil is heated to 195° in the ONBOARD® Fluid Filter where the fuel dilution, water, and liquid contaminants are evaporated and discharged sending completely clean oil back to the engine. The continuous repetition of this cycle keeps your oil clean, increases fuel economy, increases the life of the engine and eliminates the steady production of waste oil, thus reducing all the negative environmental impact associated with frequent oil changes.

Reducing Our Oil Consumption

The United States accounts for 26% of the world’s consumption of lubricating oils.

Economic growth in developing countries is spiking the demand for lubricating oils. Left unchecked, this trend will surely contribute greatly to the contamination of the Earth’s environment.

It is estimated that the United States consumes about 2.8 billion gallons of oil per year. If everyone used bypass oil filters like the ONBOARD®, the consumption would drop by about 2.3 billion to around 500 million gallons per year. A monumental step to reduce oil consumption and its impact on the environment can begin today if everyone becomes aware of their ability to contribute by adopting the ONBOARD® System. The positive impact on the environment due to the reduction of the consumption and reduction of waste oil would undeniably benefit the environment.

With only 14% of waste oil being recycled, it is our responsibility to drastically improve this number. ONBOARD® Performance Products drastically reduce oil change intervals and subsequently reduces waste oil.

Reducing Filters in the Landfills

Implementing the ONBOARD® System will dramatically advance your company’s quest to attain maximum sustainability while at the same time, bring an astounding increase to your bottom line.

The disposal of oil filters has become a concern for state governments across the country.

Oil filters contain on average, more than 10 fluid ounces of used motor oil, even after draining. Recycling programs have been established across the country to reduce the number of filters going to the landfills. Some states including California, North Carolina, and Wisconsin have recently banned or are in the process of banning oil filters from landfills. California alone generates 67 million used automotive filters per year.

Vehicles using the ONBOARD® System would also reduce the number of regular full-flow filters going into the landfills. Filters are generally changed at every oil change and high mileage vehicles can expect 8 to 15 filter changes per year. Under normal conditions, with the ONBOARD® System, you would only replace 3 to 4 ONBOARD® Particle Filters and one full-flow filter per year.